WARNING

Hazard identification

Powders produced during machining operations – sharpening, dry grinding or polishing – may irritate your skin and respiratory tract, in particular:

Nickel: no systemic effects have been recognised after an exposure to this metal. Medical surveys simply report skin or breath alternations (dermatitis). Cobalt: its inhalation may affect the skin (irritating severe dermatitis) and the respiratory tract (respiratory irritations, allergic asthma, alveolitis and diffused, interstitial fibrosis).

Cobalt was classified as A3-carcinogenic class (carcinogenic for animals). We do suggest using protective means (i.e. masks, glasses, gloves)

Remarks on disposal

Nickel and cobalt scraps must be disposed through specialised and entitled companies. Please get in touch with your supplier for more information on disposal and /or recycling.

Hazard identification

Powders produced during machining operations – sharpening, dry grinding or polishing – may irritate your skin and respiratory tract, in particular:

Nickel: no systemic effects have been recognised after an exposure to this metal. Medical surveys simply report skin or breath alternations (dermatitis). Cobalt: its inhalation may affect the skin (irritating severe dermatitis) and the respiratory tract (respiratory irritations, allergic asthma, alveolitis and diffused, interstitial fibrosis).

Cobalt was classified as A3-carcinogenic class (carcinogenic for animals). We do suggest using protective means (i.e. masks, glasses, gloves)

Remarks on disposal

Nickel and cobalt scraps must be disposed through specialised and entitled companies. Please get in touch with your supplier for more information on disposal and /or recycling.

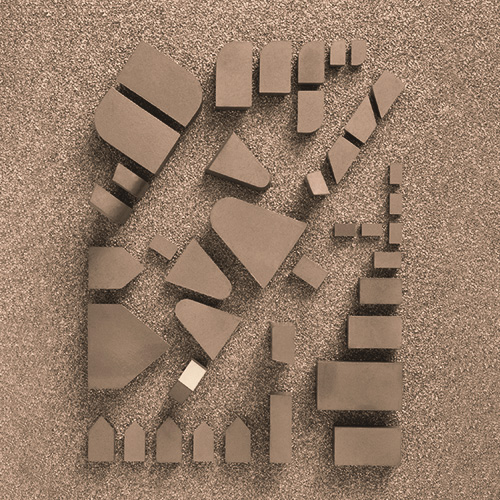

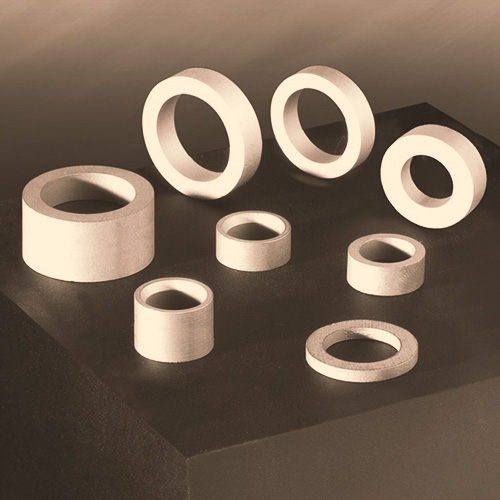

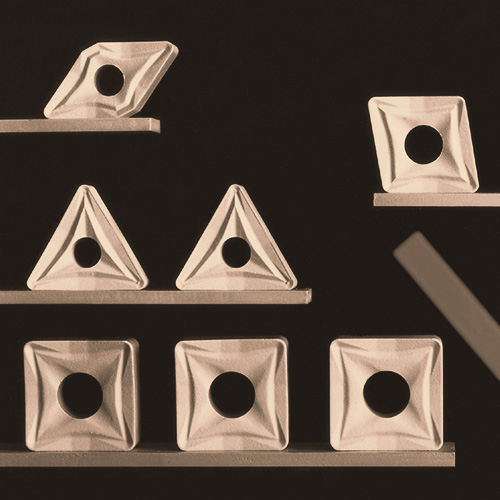

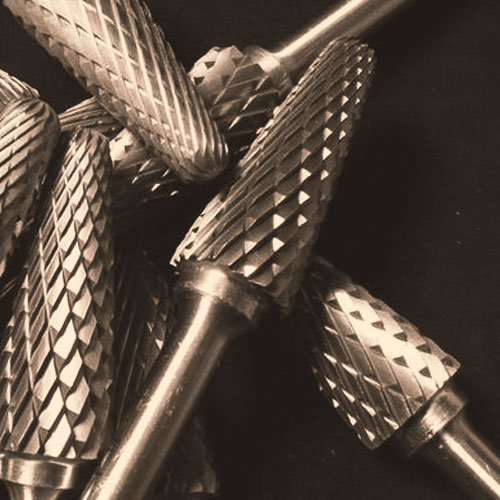

Tungsten Carbide Tools

Sintered tungsten carbide cutting tools are very abrasion resistant and can also withstand higher temperatures than standard high speed steel tools. Carbide cutting surfaces are often used for machining through materials such as carbon steel or stainless steel, and in situations where other tools would wear away, such as high-quantity production runs. Because carbide tools maintain a sharp cutting edge better than other tools, they generally produce a better finish on parts, and their temperature resistance allows faster machining.